Elevating Infrastructure with Custom Precast Concrete Textures

Unlike the typical concrete, custom precast could replicate natural stone, warm timber, or even expressive, artistic patterns, reshaping even simple structural elements into public art. This process of texturising concrete adds layers of depth and visuals, further enhancing its basic construction function.

At Ozcast Precast, we craft custom surfaces, not just pour concrete. Ozcast is dedicated to world-class architectural precast, which means that production results in all projects adhering to exact international standards.

Typically, the entire design process depends on texture because it remains the fundamental engineering and manufacturing element. With the use of liners and precision moulds, Ozcast elevates an erected structure from merely functional to simply beautifully intentional.

Selecting the right texture allows designers to reduce scale while also creating stories that link users to their environment. Ozcast brings that with real craftsmanship to every project, creating infrastructure built to last for generations.

The Technology of Texture: How We Achieve Bespoke Finishes

Designing custom tactile finishes in precast concrete requires artistic and architectural skills. Our team at Ozcast achieves consistent high-quality textures across all panels through advanced moulding systems, digital design and factory-controlled manufacturing processes.

Custom form liners are an essential element in this fabrication process. These are rubber or urethane liners placed inside the steel casting beds. From there, patterns such as stone reliefs, timber grain, or architectural motifs can be permanently imprinted on each concrete cast once cured. This method produces consistent panel items with detailed, distinct results.

Ozcast achieves additional design freedom through its CNC (Computer Numerical Control) routing system. As such, it allows master moulds to be fabricated with absolute precision and speed.

These master moulds are useful in repeated casting, allowing designers and engineers to use complex, bespoke patterns, geometric forms, organic shapes, or custom logos at scale.

Ozcast doesn’t stop at shape: we provide multiple finishing options that serve both aesthetic and functional needs.

- Off-form (Class 1/2): Using steel moulds for a smooth and refined finish. Ozcast maintains flat surface consistency through its quality control system.

- Sandblasted / Acid-Etched: The decorative aggregates become visible through controlled abrasion or chemical treatment. This results in a smooth matte finish with a soft texture.

- Polished: The diamond grinding process creates a polished surface with a reflective finish, complementing the natural characteristics of the mixture.

- Exposed Aggregate: The process of exposing decorative stone or aggregate for a tactile finish requires removal of the surface cement matrix using either retardation or washing techniques [1][2].

With Ozcast, every groove, pattern, and finish is controlled under optimal circumstances. Every panel also satisfies strict requirements, and there is no weather-related variability.

This level of precision and repeatability is what Ozcast brings from small to large-scale projects, all while ensuring design ambition and manufacturing consistency.

Applications: Where Texture Adds Value

Textured precast concrete serves decorative purposes, but also adds value, unique identity, and long-lasting durability to infrastructure.

Here are a few core applications where texture elevates Ozcast’s projects:

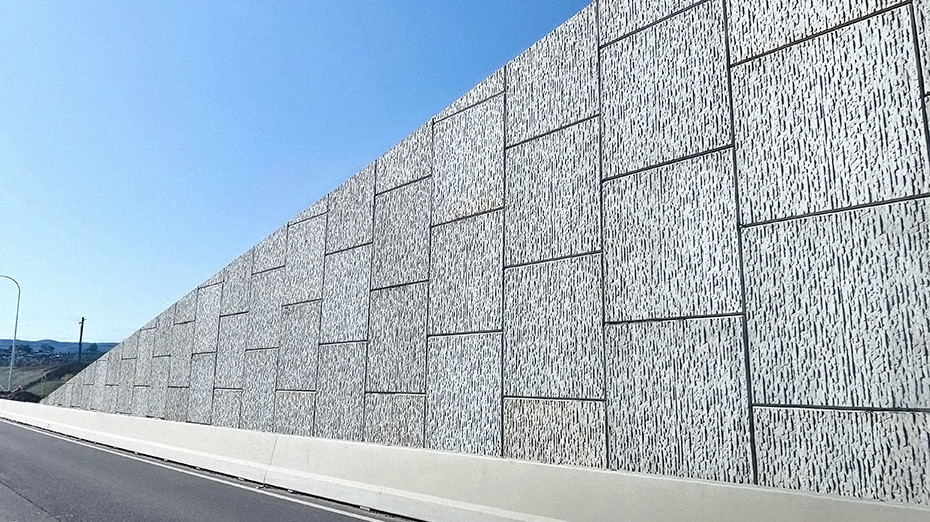

Precast Noise Walls

Noise walls typically stretch for long distances and dominate visual sightlines. Ozcast uses vertical ribbing, stone-like textures, and engraved graphics to replace the plain flat surfaces. The Heathcote Road project shows how these textured panels add visual interest while unifying with local surroundings to create artistic continuity and reduce road noise.

Retaining Walls

In landscape projects such as parklands or natural reserves, retaining walls should feel less like concrete barriers and more like part of the natural spaces. Reinforcing timber-grain textures creates a natural appearance that helps it blend with green spaces, tracks and bushland settings.

Parapets & Traffic Barriers

Highway and bridge safety depends on parapets and barriers, though they don’t need to serve only as protective components. Ozcast can embed geometric motifs or council insignia into these surfaces, reinforcing civic identity and elevating infrastructure beyond a mere barrier.

Tilt-Up Panels

The use of tilt-up construction could result in uninteresting structures that often consist of plain, smooth panels. By introducing architectural grooves, false jointing, or recessed patterns, it helps break up facades and create visual depth, adding interest without compromising structural performance [3].

Across all these applications, Ozcast demonstrates remarkable versatility. From a lengthy highway wall to a building façade and public space furniture, we adapt moulding and casting capabilities to scale. This way, every infrastructure enriches the natural spaces and human experience.

Beyond Texture: Shape and Form (Street Furniture & Structures)

At Ozcast, our precast concrete blends form, function, and design in every fabrication. To accomplish this, texture is important, forming concrete into flowing, complex, sculptural shapes that complement every build.

Take precast street furniture, such as benches, planters, or public seating. These often feature an organic, curved bench with a smooth, ergonomic design that integrates perfectly with public landscapes. Crafting such requires CNC-carved masters, flexible liners, and layered formwork to create sweeping arcs and fluid radii.

The factory environment matters in every build’s shape and form. At Ozcast, we produce custom concrete forms off-site to create elements that match both structural requirements and design specifications.

This process allows users to control curing, surface finish quality, lift-point placement, and reinforcement. Unlike many precast yards that shy away from difficult shapes, Ozcast leans in, specialising and delivering what others avoid.

This craftsmanship positions Ozcast as an artisan manufacturer: we sculpt concrete that adds textural depth, design and function. Our team’s expertise in handling curves, organic shapes, and ergonomic designs enables designers to handle simple to more complex designs

The Benefits of Textured Precast

Why choose textured precast over plain concrete? Though dependent on a project goal, it provides practical, aesthetic, and long-term advantages, and Ozcast specialises in bringing these aspects.

- Graffiti Mitigation: Heavily textured surfaces put off tagging. Spray painting becomes very challenging on these surfaces, which are mostly irregular shapes, deep reliefs, and ribbing patterns, thereby reducing repair or maintenance costs.

- Placemaking & Aesthetics: Textured surfaces elevate infrastructure into art. Buildings achieve location identity through distinct design elements that honour local heritage and the natural environment. Instead of adding visual clutter, it provides depth, meaning, and local identity.

- Durability & Ageing Gracefully: Textured surfaces also perform better than flat concrete at concealing dirt. Besides showing less wear and weathering effects, it develops distinct characteristics that make the finished product remain visually appealing for numerous years, even after installation.

- Legacy Value: Every textured piece brings immediate visual appeal, maintaining its charm as it ages. Often present in legacy assets, textured precast builds structural integrity and community pride that endures external changes.

In infrastructure, texture isn’t just decoration on display or a colourful design. At Ozcast, we add texture to every precast concrete to maximise appeal, function and durability, while prioritising safety and reducing upkeep in every build.

Concrete serves as a functional material while also doubling as an artistic medium. The combination of texture, form, and precision results in a permanent representation of location, purpose, and design.

Ozcast combines artisanal skills with industrial production methods to transform basic infrastructure into artistic functional elements. Contact Ozcast to discuss your next project.

Sources

- National Precast Concrete Association Australia – Finishes – Classes, quality and colour of off-form grey precast

- Precast Concrete Australia – Precast finishes guide

- Global Precast – Architectural precast specification