The Complete Guide to Precast Concrete Parapets in Australian Infrastructure

Besides keeping vehicle motion in check, these structures also protect pedestrians and reduce crash impacts. Put simply, these fitted resilient barriers protect both road users and nearby communities.

Before roadside placement, every parapet’s design and construction need to adhere to Austroads guidelines and AS 5100 bridge design standards to meet requirements for impact resistance, weather exposure, and long-term durability [1][2].

Across Australia, government agencies and project managers heavily rely on solutions that combine strength, safety, and long-term durability. The construction of bridges, elevated roadways and complex transport corridors requires precast parapets to meet the highest safety standards.

At Ozcast Precast, safety and quality are the cornerstones of everything we produce. We don’t just manufacture concrete components, but ensure each serves as a life-saving system.

Every parapet profile, reinforcement pattern, and mix design is created with an understanding of how critical these barriers are to public safety. Ozcast’s commitment to quality control directs every step of our production process, from design through manufacturing to testing for Australian projects that need precast parapets.

The Three Categories of Barrier Systems

Barrier systems within Australian road and bridge networks fall into three main categories. Each type of containment system performs distinct functions based on the location, containment needs and design limitations.

Rigid Concrete Barriers

This functions as the most effective containment system, generating minimal movement after impact. It also keeps any vehicle size from veering off the road during high-impact collisions.

Such features ensure that every unit is suitable for bridges, elevated roadways, central medians and viaducts. Its materials stay intact when hit by a vehicle, reducing the likelihood of vehicle rollovers.

Semi-rigid Systems

It includes W-beam and Thrie-beam designs made of steel rails that deform on impact. This system cushions the impact force during road collisions. It also operates with concrete bases in places where visibility and pedestrian movement, and maintenance activities need to be maintained.

Semi-rigid barriers are common along highways, bridge paths, and locations that require a balance between containment and flexibility.

Custom and Architectural System

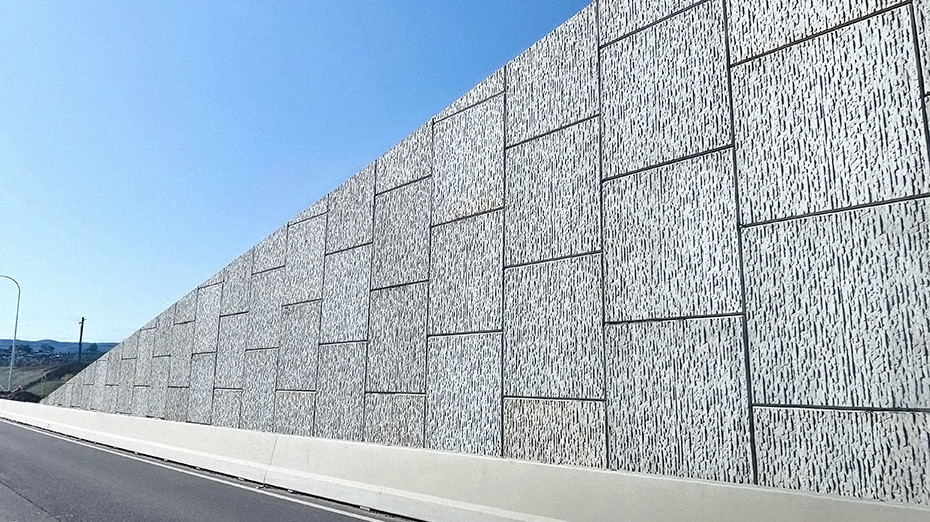

Suited to urban areas, the integration of custom and architectural systems blends functional requirements with aesthetic design. This parapet type displays various shapes, incorporating sound-dampening elements and decorative surfaces.

Custom parapets are also fit for projects that hinge on protecting local character, visual impact, and placemaking elements.

At Ozcast, we manufacture all three barrier types, including hybrid systems that combine reinforced concrete with steel rail attachments. The system provides various options that enable engineers and government clients to select the suitable type for their site based on safety requirements, design standards, and regulatory rules.

Rigid Precast Parapets: Profiles & Functions

Rigid precast parapets are central safety structures that protect all bridges and roadways throughout Australia. These are precision-engineered for high containment performance, with predictable behaviour, making it the preferred choice in locations where failure is not an option.

To explore each profile in detail, it is important to understand why rigid parapets matter. While a vehicle’s shape controls how it experiences a sudden crash, these rigid structures curb rollover accidents and prevent additional crashes.

Listed below are the three most common rigid parapet/barrier profiles used across Australian infrastructure:

The F-Type Barrier

The F-Type barrier is widely recognised as the Australian standard for high containment. Its design typically includes a stepped pattern that raises vehicle wheels during collision events.

The upward lift system halts vehicles from flipping over while also keeping the car steady when it returns to its travel lane. This is typically used on bridges, elevated motorways, and major arterial roads, where predictable crash behaviour is essential.

Such a system relies on local crash data to perform well at high speeds. With that, the parapet design functions to spread impact forces. This protects structural elements and improves safety outcomes for extended periods.

The Jersey Barrier

This barrier type is one of the most recognisable parapet shapes worldwide. The lower section of the barrier, often sloped, functions as an impact absorber, while the upper section directs vehicles back onto the road.

These core features make these erected structures suitable for use in medians, construction zones, and road corridors that need either temporary or permanent containment.

While it originated in the United States, this barrier type serves as an economical, practical solution for Australia when positioned in extended roadway sections that need ongoing direction changes.

The Single Slope Parapet

Single-slope parapets are becoming more common in Australian roads as they provide sustained, reliable performance. Its design features a continuous straight slope, which separates it from stepped or multi-angled barriers.

Its geometry system provides stable redirection when pavement height changes due to resurfacing. Since the single-slope design eliminates the need to adjust barrier height for upcoming pavement projects, it potentially reduces maintenance needs and improves lifecycle value.

This barrier type also provides engineers and asset owners with an easy-to-use containment system, which delivers impressive results.

Technical Strength & Reinforcement

Rigid precast systems rely on strong concrete and reinforcement to withstand impact loads. Typical parapets are manufactured using concrete mixes ranging from 40 to 50 MPa, depending on the project requirements.

The design of reinforcement cages is important to prevent cracks, withstand tensile impact forces, and maintain the parapet’s structural integrity throughout its operational life [2].

At Ozcast, each parapet is reinforced to meet or exceed AS 5100 requirements, ensuring consistent performance across all installations.

Semi-Rigid & Hybrid Systems

Semi-rigid barriers perform functions that differentiate them from rigid concrete systems. These absorb energy via controlled deformation instead of just resisting impact with minimal deflection. It reduces the force that hits vehicles during crashes, minimising injury severity.

In bridge environments, where pedestrians and cyclists share space with vehicles, semi-rigid systems are typically combined with precast concrete bases. The concrete section of the barrier system maintains stability while resisting impacts, but the steel rail components, including W-beam or Thrie-beam rails, provide visibility and absorb energy.

Its design process benefits from hybrid systems, allowing optimal performance without losing visual flair. For example, a concrete base ensures structural durability, while the steel component permits airflow and clearer sightlines.

By combining these two materials, it appears on shared paths, pedestrian bridges, and urban corridors, meeting safety standards and creating visually appealing spaces.

At Ozcast, we produce both concrete-compatible and steel-compatible bases. This allows us to create a unified system that provides engineers with dependable mixed-use solutions.

Custom & Architectural Parapets

Australian cities heavily rely on infrastructure design that supports safety requirements and a unique visual identity. Custom and architectural parapets are well-suited for these reasons, maintaining operational value and visual appeal of urban areas.

Noise-reducing barriers can be combined with architectural parapets to build environmental improvements. Custom profiles often include thicker wall sections, acoustic-absorbing shapes, or integrated textures that reduce traffic noise.

Architectural parapets may be attributed to:

- Anti-graffiti coatings to reduce maintenance

- Coloured concrete for visual integration with urban design plans

- Distinct, textured form liners that mimic stone, timber, or artistic patterns

The parapet solutions enable councils, architects, and state agencies to unite infrastructure elements with local design principles while fulfilling rigorous safety requirements.

Ozcast provides advanced moulding and custom casting capabilities to produce parapets that serve both placemaking needs and noise-control requirements. Our team crafts and installs every unit to meet long-lasting performance standards built to last for many years to come.

Precast vs. In-Situ: Why Precast Wins

Precast parapets offer superior performance compared to other in-situ construction methods in most places that demand quick project dispatch and minimal traffic disruption.

- Quality: Factory-based precast fabrication controls external factors, such as temperature, moisture, curing times, and mix proportions. That way, each barrier is strong and reliable, which is tricky with on-site pours that depend on the weather conditions.

- Speed: Precast units arrive and are ready to go. This reduces both traffic interruptions and lane shutdowns, while minimising the number of workers needed on-site. This is essential for government projects, as fast installation means less public disruption.

- Consistency: Since every unit is made the same way, they fit together perfectly, look uniform, and perform reliably. Precast manufacturing guarantees identical profiles, reinforcement patterns, and surface finishes across all units. The system maintains a consistent barrier structure, and it installs easily and operates reliably.

Precast systems maintain a consistent, reliable barrier, unlike in-situ methods. These advantages make precast the preferred option for modern infrastructure projects across Australia.

Standards & Compliance (AS 5100 & Austroads)

Road and bridge parapets must always follow basic safety compliance. The performance standards and selection procedures for these systems operate within two distinct frameworks in Australia.

AS 5100.1:2017 sets standards for material characteristics, minimum concrete strength requirements, impact load testing, and barrier performance evaluation. It ensures that parapets can withstand collision forces and maintain their structural integrity over decades of service [2].

Meanwhile, Austroads AP-G108-25 enables project managers to select the right barrier system by evaluating road design elements, vehicle speed limits, traffic density, and safety hazards on-site. This provides designers with methods for assessing containment performance and choosing the right parapet profile [1].

All Ozcast parapets include complete QA documentation, batch testing data, and compliance certificates. The testing process helps engineers and contractors identify all safety-critical barriers, which must remain in place before starting site operations.

Choosing the right parapet means considering its safety, effectiveness, site conditions, aesthetic standards, and how quickly it performs.

Australian infrastructure depends on precast solutions because not only are they a popular choice, but they also provide consistent quality, meet requirements reliably, and get the job done fast.

Do you need technical advice on AS 5100-compliant parapets? Contact us at Ozcast Precast for specialised guidance on your next project.

Sources

- Standards Australia – Bridge design, Part 1: Scope and general principles