Why Government Infrastructure is Shifting to Precast Wall Systems

As what once worked can’t shoulder the load anymore, projects are relying more on precast wall systems. Unlike traditional on-site construction methods, it addresses infrastructure demands by moving time-intensive and risk-heavy construction to a controlled factory environment.

Simply put, precast systems allow faster installation, reducing on-site labour requirements while ensuring consistent quality and precision at scale. Durable precast panels can be assembled and installed in hours, reducing construction windows and public disruption.

At Ozcast, we know and understand the weight shaping Australia’s construction future. This is why we excel in project acceleration, aiding government agencies and Tier 1 contractors in delivering safer, faster, and more predictable outcomes through precision-engineered precast solutions.

Speed, Safety, and Minimising Public Disruption

Infrastructure projects, whether private or government-based, rarely happen in quiet, isolated spaces. These typically occur in live traffic corridors, school zones, commuter routes, and freight networks, which cannot be shut down for weeks to accommodate an infrastructure project.

Think of every hour a lane is closed due to construction – this adds to congestion, public frustration, and pressure circling the government. With precast wall systems, the number of workers and equipment on-site is reduced, curtailing the space required for construction and disruptions.

Precast’s real advantage in the changing infrastructure landscape is its high-speed installation. It can be installed in minutes, allowing overnight installation and reopening roads before morning traffic even begins. These fast-track projects are unlike typical on-site methods and extended construction periods.

Since it also requires fewer workers within live traffic, precast solutions are safer than traditional ones. Besides that, it substantially reduces the number of traffic control setups and equipment, creating a much safer environment for both the public and the workers.

This is where Ozcast excels, putting safety and efficiency at the forefront of every project. Our team optimises logistics and just-in-time delivery so installation crews can hasten building completion.

Our precast solutions reduce road congestion, enhance the safety of building spaces, and help government agencies meet project milestones on schedule. Ozcast is the top choice for infrastructure projects where speed, safety, and public satisfaction are non-negotiables.

Case Study: The Heathcote Road Upgrade

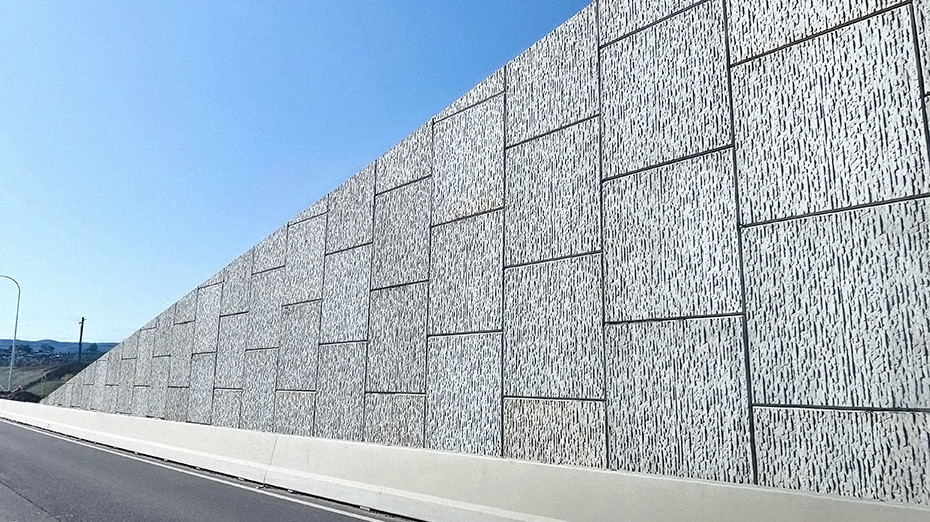

The Heathcote Road Upgrade is a prime example of why precast infrastructure matters, delivering both structural performance and genuine community value.

The NSW Government commissioned this project to ease congestion, reduce travel times, and safeguard nearby areas impacted by road noise, such as childcare centres, family homes, and local shops.

Heathcote Road is a major arterial link, but the area’s prolonged traffic has raised noise levels and safety concerns for residents along the corridor. This set the noise mitigation system in motion, incorporated into the road upgrades, while preserving the community’s heritage and identity.

This meant the solution needed not just any barrier, but also to prioritise placemaking, storytelling and technical precision to turn a typical barrier into a safe, visual and functional asset.

Ozcast produced and supplied 166 architecturally engineered precast panels designed to deliver quality acoustic attenuation while effortlessly incorporating into the new road corridor. Each panel passed through successive quality control stages, meeting tight installation windows to minimise public disruption.

What makes the precast wall system stand out even more is the custom artwork included in the panels. This was made possible by working closely with Transport for NSW and project designers, which helped Ozcast bring to life historic photographs, some over 80 years old, through a series of bespoke concrete engravings.

These engraved images collectively depicted the Heathcote’s rich history, its early residents, and its connection to the bushland that gives meaning to the region.

This required careful, strategic planning from start to finish. Each engraving found on the precast panels required:

- Single-use, custom-made form liners, engineered and fitted to create crisp, durable impressions on the panels.

- Precise concrete mix design that ensures depth consistency and panel longevity.

- Meticulous production sequencing to perfectly align each panel before on-site installation.

These panels were full-scale artworks cohesively blended with the structural, load-bearing noise walls. Besides noise and traffic control, this resulted in one of the few unique pieces of road structures in NSW.

This project puts Ozcast’s capability on display, far beyond typical wall production. We specialise in high-complexity precast systems that combine engineering excellence with positive community impact.

The Heathcote Road Upgrade is a cemented validation, establishing Ozcast as a placemaking partner capable of delivering legacy outcomes.

Quality Assurance and 100-Year Durability

Government infrastructure must deliver value and withstand any elements for decades. As such, the adoption of materials and methods that support structures that could last for a century has become a standard best practice for Transport for NSW (TfNSW) and Council assets [1].

Infrastructures designed to last longer directly slash lifecycle expenses. This ensures every erected building withstands harsh conditions, without repeated repairs or upgrades that could be costly and disruptive when built on public property [2].

Precast concrete performs very well in long-term asset planning, as technicians craft each panel in a factory-controlled setting. Built offsite, it operates and remains unaffected by weather, moisture levels, and curing inconsistencies.

Traditional construction methods often hit a dead end, vulnerable to cracking and early deterioration. Precast’s controlled environment easily sidesteps these structural risks. Manufacturers cast each unit with calibrated equipment, monitored curing, and strict batching controls that meet engineering specifications at every cycle.

The Austroads Guide to Bridge Technology, together with other independent national guidelines, identifies durability and controlled curing as required elements for creating concrete assets that last [3].

When it comes to asset ownership costs, precast panels need very little upkeep to function effectively, even in extreme conditions. This trims operational expenses for the long haul, as it requires fewer personnel to maintain, reinstall or upgrade.

At Ozcast, every precast panel undergo a series of quality tests, ensuring structural durability and performance for the years to come. That’s why Ozcast works fully as the safe hands for government projects.

From upgrades to large-scale builds, we test, inspect, and verify each panel before it leaves the facility, ensuring all units meet the highest standards for quality and safety.

Sustainability and Waste Reduction

The Australian government faces growing demands to implement ESG strategies while working towards Net Zero 2050. With its net-zero plan for resource efficiency, waste and emissions reduction, precast has these objectives in its corner [4].

Precast factories substantially reduce heaps of waste that on-site construction cranks out, including from failed pours, offcuts, and leftover materials. Thanks to its streamlined material use, precast uses precise formwork and reusable steel casting beds, minimising landfill output.

Australia’s Green Building Council studies reveal that controlled manufacturing methods reduce construction waste by 50%, as opposed to conventional building methods [5].

Besides material efficiency, precast panels offer long-term operational sustainability. It uses durable material that requires no regular maintenance, curbing the carbon emissions during the assets’ complete lifecycle.

Precast walls also strengthen social sustainability, particularly in residential and mixed-use corridors. These panels provide soundproofing properties, blocking out noise from highways, railways, and industrial areas to create better living conditions. It also advances the government’s liveability objectives by aligning with planning frameworks.

Ozcast’s production facility is designed around these environmental principles. Selecting precast products from manufacturers that support healthier, quieter, and more resilient communities helps agencies build the infrastructure of tomorrow.

Precast concrete gives government teams a smart way to build infrastructure that lasts longer. It allows projects to move faster without cutting corners, so they’re done on time and built to the highest standards.

Precast panels are strong, sustainable, and made with consistent precision, ensuring excellent performance for years and benefit the communities that rely on them. It’s a practical, efficient approach that brings real value to modern public projects.

Does your next infrastructure project require complex bespoke panels or rapid delivery? Contact Ozcast Precast to discuss our government capability statement today.

Methods & Sources

- Transport for NSW – Asset lifecycle and durability expectations

- Infrastructure Australia – Sustainability principles and lifecycle planning

- Austroads Guide to Bridge Technology – Durability principles

- Australian Government Department of Climate Change, Energy, the Environment and Water – Net Zero 2050 Framework

- Green Building Council of Australia – Construction waste reduction principles